The three-day dockworkers strike that shut down East and Gulf coast port operations from Maine to Texas last week appears not to have dented the nation’s flow of imported goods, according to the latest monthly report from the National Retail Federation (NRF) and Hackett Associates.

Imports at the nation’s major container ports should continue at elevated levels this month despite the strike, the groups said in their Global Port Tracker report.

To be sure, the strike wasn’t without impacts. NRF found that retailers who brought in cargo early or shifted delivery to the West Coast face added warehousing and transportation costs. But the overall effect of the three-day work stoppage on national economic trends will be fairly muted.

“It was a huge relief for retailers, their customers and the nation’s economy that the strike was short lived,” NRF Vice President for Supply Chain and Customs Policy Jonathan Gold said in a release. “It will take the affected ports a couple of weeks to recover, but we can rest assured that all ports across the country will be working hard to meet demand, and no impact on the holiday shopping season is expected.”

Looking at next steps, NRF said the focus now is on bringing the International Longshoremen’s Association (ILA)—the union representing some 45,000 workers—and the United States Maritime Alliance Ltd. (USMX) back to the bargaining table. “The priority now is for both parties to negotiate in good faith and reach a long-term contract before the short-term extension ends in mid-January. We don’t want to face a disruption like this all over again,” Gold said.

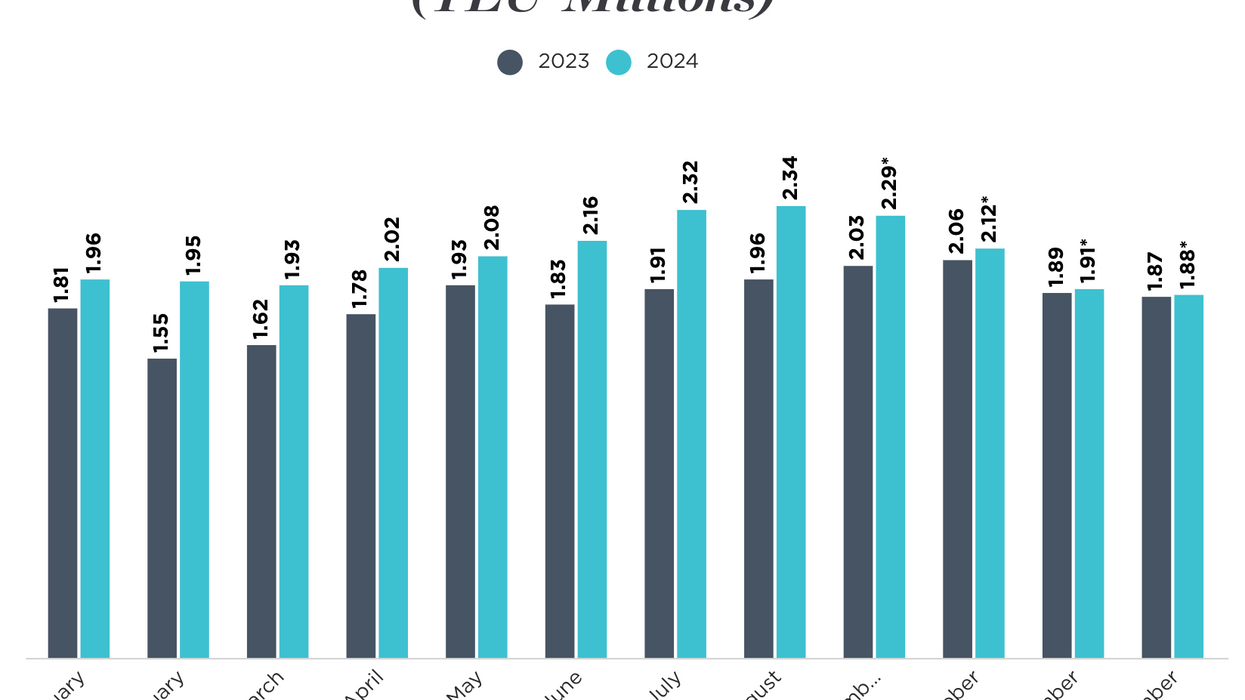

By the numbers, the report forecasts that U.S. ports covered by Global Port Tracker will handle 2.12 million twenty-foot equivalent units (TEU) for October, which would be an increase of 3.1% year over year. That is slightly higher than the 2.08 million TEU forecast for October a month ago, and the strike did not appear to affect national totals.

In comparison, the August number was 2.34 million TEU, up 19.3% year over year. The September forecast 2.29 million TEU, up 12.9% year over year, November is forecast at 1.91 million TEU, up 0.9% year over year, and December at 1.88 million TEU, up 0.2%. For the year, that would bring 2024 to 24.9 million TEU, up 12.1% from 2023. The import numbers come as NRF is forecasting that 2024 retail sales – excluding automobile dealers, gasoline stations and restaurants to focus on core retail – will grow between 2.5% and 3.5% over 2023.

Global Port Tracker, which is produced for NRF by Hackett Associates, provides historical data and forecasts for the U.S. ports of Los Angeles/Long Beach, Oakland, Seattle and Tacoma on the West Coast; New York/New Jersey, Port of Virginia, Charleston, Savannah, Port Everglades, Miami and Jacksonville on the East Coast, and Houston on the Gulf Coast.