Container imports at U.S. ports are seeing another busy month as retailers and manufacturers hustle to get their orders into the country ahead of a potential labor strike that could stop operations at East Coast and Gulf Coast ports as soon as October 1.

Less than two weeks from now, the existing contract between the International Longshoremen’s Association (ILA) and the United States Maritime Alliance covering East and Gulf Coast ports is set to expire. With negotiations hung up on issues like wages and automation, the ILA has threatened to put its 85,000 members on strike if a new contract is not reached by then, prompting business groups like the National Retail Federation (NRF) to call for both sides to reach an agreement.

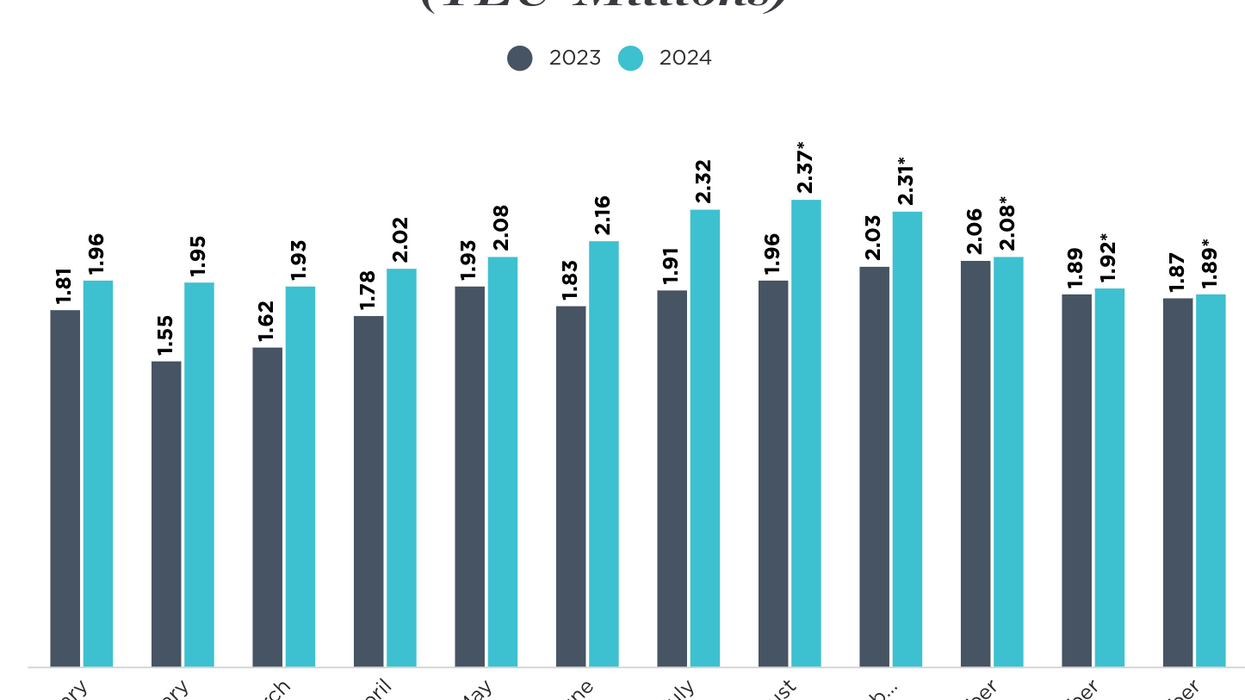

But until such an agreement is reached, importers are playing it safe and accelerating their plans. “Import levels are being impacted by concerns about the potential East and Gulf Coast port strike,” Hackett Associates Founder Ben Hackett said in a release. “This has caused some cargo owners to bring forward shipments, bumping up June-through-September imports. In addition, some importers are weighing the decision to bring forward some goods, particularly from China, that could be impacted by rising tariffs following the election.”

The stakes are high, since a potential strike would come at a sensitive time when businesses are already facing other global supply chain disruptions, according to FourKites’ Mike DeAngelis, senior director of international solutions. “We're facing a perfect storm — with the Red Sea disruptions preventing normal access to the Suez Canal and the Panama Canal’s still-reduced capacity, an ILA strike would effectively choke off major arteries of global trade,” DeAngelis said in a statement.

Although West Coast and Canadian ports would see a surge in traffic if the strike occurs, they cannot absorb all the volume from the East and Gulf Coast ports. And the influx of freight there could cause weeks, if not months-long backlogs, even after the strikes end, reshaping shipping patterns well into 2025, DeAngelis said.

With an eye on those consequences, importers are also looking at more creative contingency plans, such as turning to air freight, west coast ports, or intermodal combinations of rail and truck modes, according to less than truckload (LTL) carrier Averitt Express.

“While some importers and exporters have already rerouted shipments to West Coast ports or delayed shipping altogether, there are still significant volumes of cargo en route to the East and Gulf Coast ports that cannot be rerouted. Unfortunately, once cargo is on a vessel, it becomes virtually impossible to change its destination, leaving shippers with limited options for those shipments,” Averitt said in a release.

However, one silver lining for coping with a potential strike is that prevailing global supply chain turbulence has already prompted many U.S. companies to stock up for bad weather, said Christian Roeloffs, co-founder and CEO of Container xChange.

"While the threat of strikes looms large, it’s important to note that U.S. inventories are currently strong due to the pulling forward of orders earlier this year to avoid existing disruptions. This stockpile will act as an essential buffer, mitigating the risk of container rates spiking dramatically due to the strikes,” Roeloffs said.

In addition, forecasts for a fairly modest winter peak shopping season could take the edge off the impact of a strike. “With no significant signs of peak season demand strengthening, these strikes might not have as intense an impact as historically seen. However, the overall impact will largely depend on the duration of the strikes, with prolonged disruptions having the potential to intensify the implications for supply chains, leading to more pronounced bottlenecks and greater challenges in container availability, " he said.