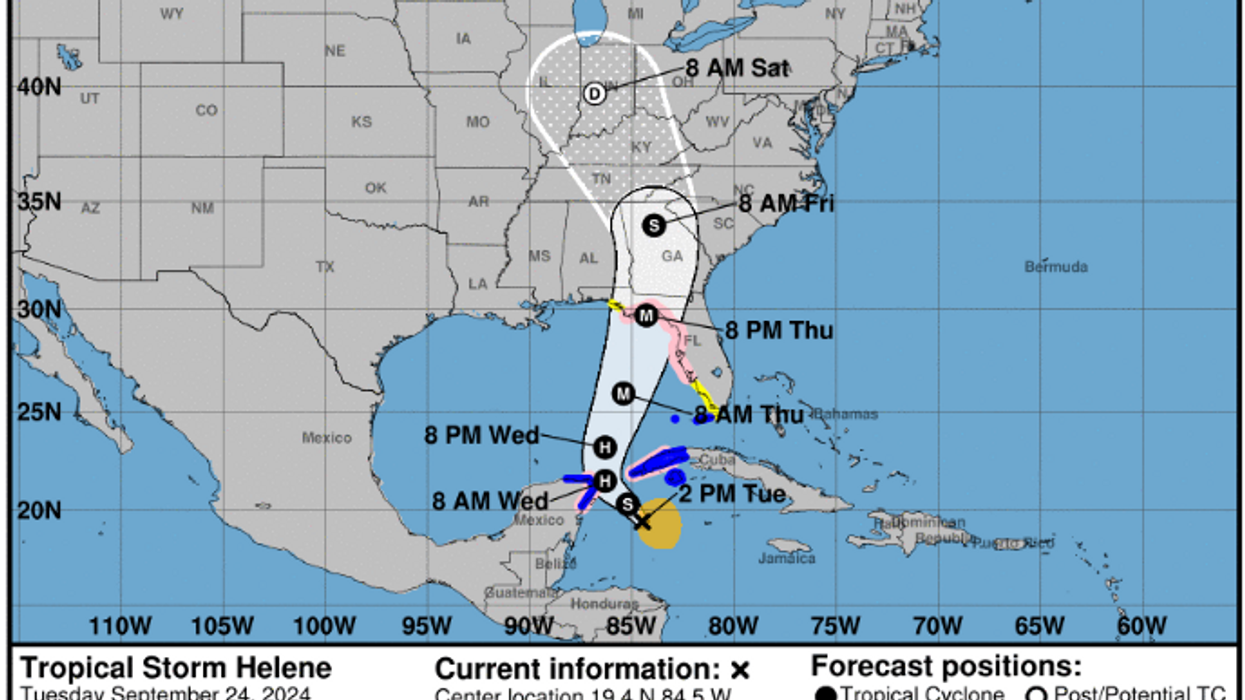

Residents and businesses along the Florida panhandle today are keeping a close eye on Tropical Storm Helene, which is forecasted to strengthen into a major hurricane by the time it strikes the northeast Gulf Coast on Thursday.

Hurricane and storm surge watches are already in effect for that area, which could see heavy rain and flash flooding across portions of Florida, the Southeast U.S., Southern Appalachians, and the Tennessee Valley, according to predictions from the National Hurricane Center.

The storm would come a month after Hurricane Debby delivered drenching rainfall for days over Florida in August and after Hurricane Beryl hit Houston in July, knocking out power across the region.

As Helene continues to gather strength from the warm waters of the Gulf of Mexico, experts are warning that the storm’s impacts could include the Port of New Orleans, agricultural operations throughout the Southeast, and additional citrus and fruit farming business in Florida, according to a report from Everstream Analytics’ chief meteorologist Jon Davis.

From a supply chain perspective, additional disruptions could include rail and road transportation stoppages, closures of interstate highways I-10 and I-75, widespread power outages, and shutdowns of offshore energy operations in the eastern portion of the Gulf of Mexico, Davis said.

As the third potential hurricane to hit the area within as many months, the arrival of Helene shows that extreme weather events aren’t just anomalies, but rather they’re the new normal for shipping companies and port authorities, according to Frank Kenney, Director of Industry Strategy at the technology consulting firm Cleo.

To cope with that constant battering, businesses need to adopt a new mindset, he said. “The only way to keep supply chains running smoothly is to build resilience into every aspect of operations. This starts with diversifying logistics strategies. If a shipper is dependent on a single route or port, they’re setting themself up for trouble. Instead, it’s crucial to have multiple backup routes and options ready to deploy when the unexpected happens,” Kenney said.

Following that strategy, inland ports such as Savannah and Macon, Georgia, will likely gain importance in coming years since their locations offer proximity to ocean ports while also providing access to major highways and some protection from coastal flooding. “In short, the storm isn’t going away, but by embracing diversification, leveraging technology, and ensuring supply chain visibility, U.S. ports and shipping companies can stay ahead of the curve. The companies that prepare for these challenges now will be the ones that continue to thrive, no matter how extreme weather events rock the boat," Kenney said.