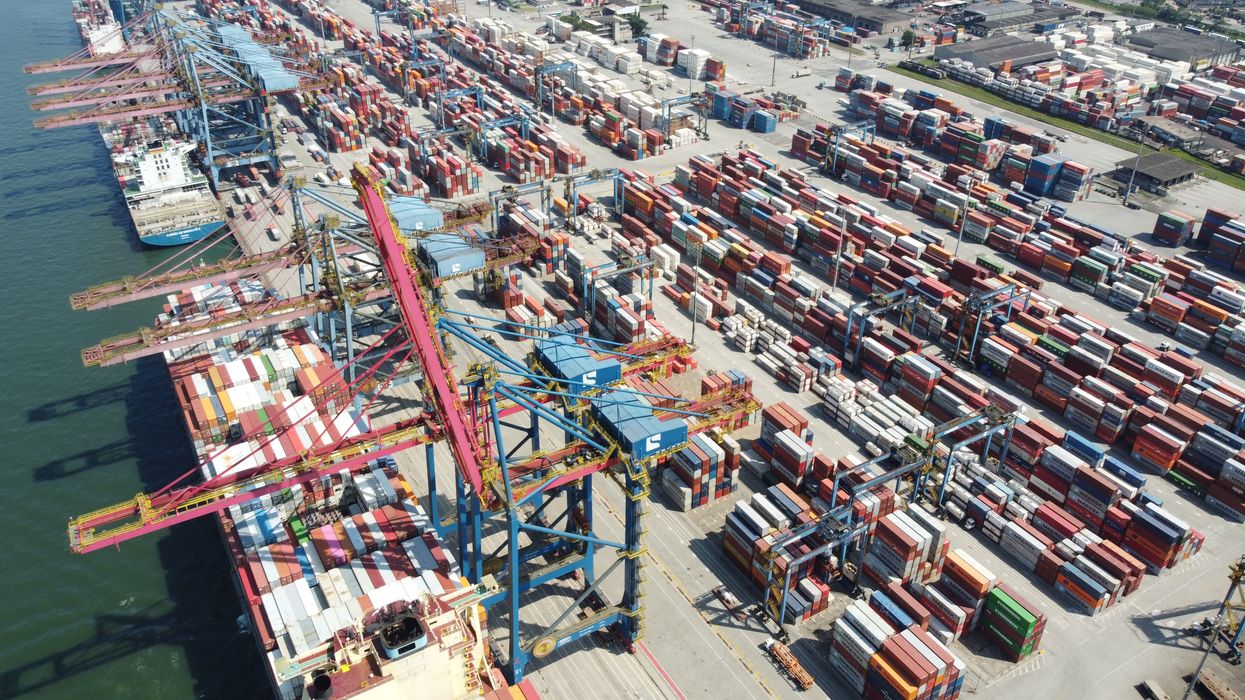

The French container shipping and logistics provider CMA CGM Group has agreed to acquire nearly half of Santos Brasil Participações S/A, a Brazilian multi-terminal operator that manages South America’s largest container terminal, which is located at the Port of Santos.

CMA CGM will purchase a 48% stake in the company from its current owner, Opportunity Funds. Santos Brasil manages a portfolio of 8 assets on the Brazilian coast, including 3 Container Terminals, 1 Vehicle Terminal, 1 Liquid Bulk Terminal, and 3 Logistic Facilities. These assets are located in the Ports of Santos, Imbituba, Vila do Conde, Itaqui and in Sao Paulo.

Once the acquisition closes, CMA CGM intends to further develop its line calls in the various Brazilian terminals and further improve its offering to Brazilian exporters and importers, thereby responding to increasing demand and better addressing consumer needs.

The move will also enable CMA CGM to offer “seamless connections” between Europe, Asia, North America, and the Caribbean, thus solidifying Brazil's position as a key hub in the group’s worldwide operations and reinforcing synergies with its MERCOSUL Line affiliate.

The deal marks CMA CGM’s latest move to expand its port holdings, reinforcing its position as a leading global multi-user terminal operator with investments in approximately 60 terminals worldwide, the company said.

“I am pleased that the CMA CGM Group has concluded this strategic agreement for the acquisition of Santos Brasil, which operates five terminals in Brazil, including the largest container terminal in the Port of Santos, handling 40% of Brazilian volumes, as well as a logistics company. This significant investment reflects our commitment to strengthening our partnership with Brazil and supporting its growth in the coming years,” Rodolphe Saadé, CEO of CMA CGM Group, said in a release.