As a global leader in the cosmetics industry, L'Oréal is held to stringent standards across their supply chain. In many of their warehouses they depend on Dematic Automated Guided Vehicles (AGVs) to maintain general standardization.

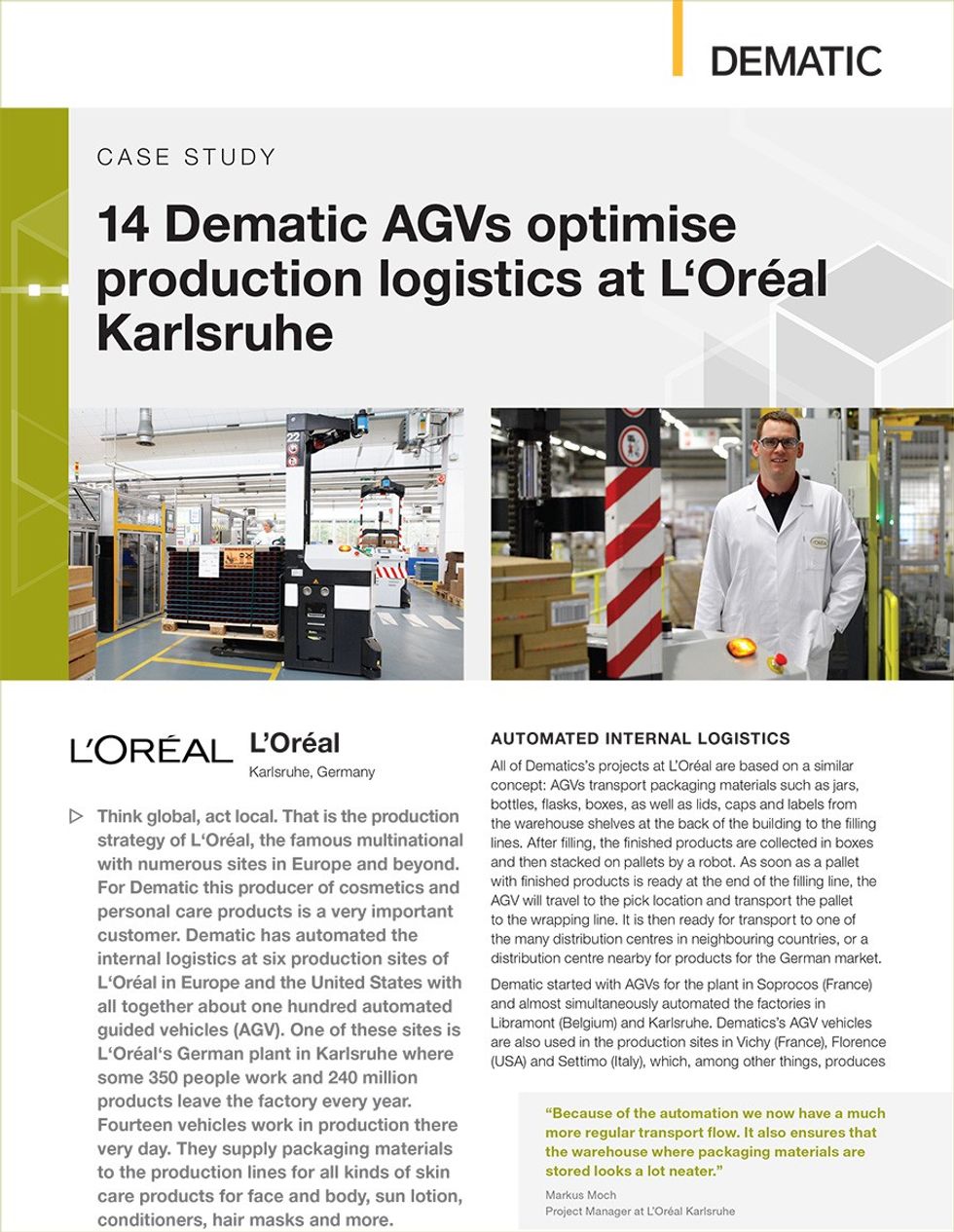

A fleet of AGVs is now used to perform tasks that were previously done by production staff. They work both smoother and more safely across three daily shifts and have optimized the teams' workflows. They transport packaging from shelves to filling lines, finished products to shipping stations, and follow assignments given by staff to perform tasks that include transferring empty pallets, picking up cardboard, and arranging the removal of packaging materials. The AGVs follow clearly marked routes and stop automatically for any obstacles, allowing for efficient transport flow, a neater warehouse, and safer working conditions.

Read the full case study to learn how this highly flexible and user-friendly solution allows L'Oréal to customize operations for future growth and continuous optimization.

Sponsored By Dematic

Sponsored By Dematic