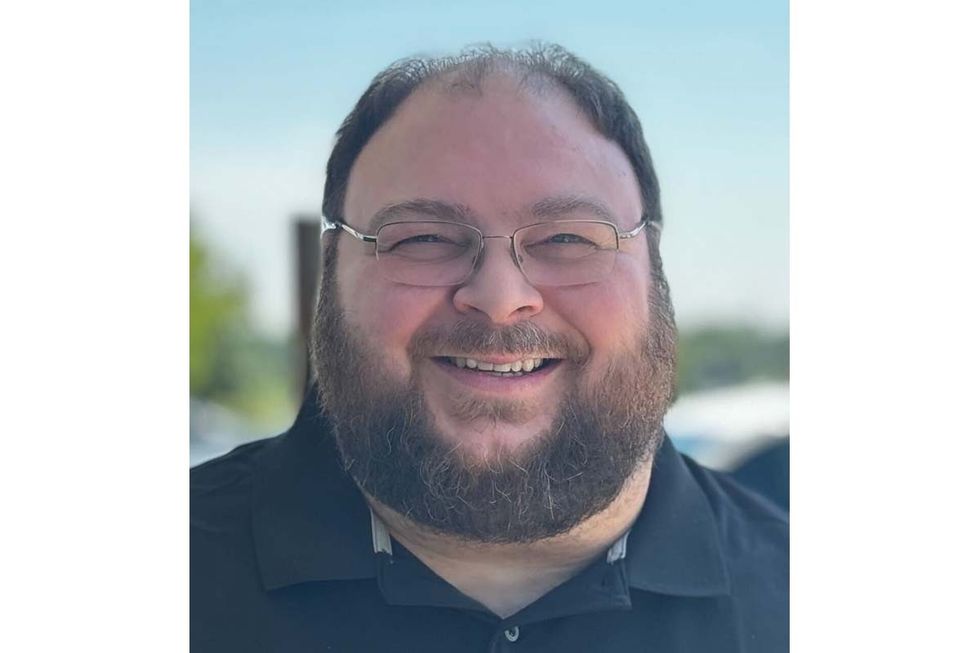

Nick Gentile is vice president of operations at Savety Yellow Products, a warehouse safety products and solutions business founded by his parents in 2003. Gentile grew up in the family business. As a teenager he did everything from basic office work to working the paint line and helping in the manufacturing processes. Today, Gentile’s primary role is overseeing the day-to-day operations of purchasing, production, sales, staffing, training, and the warehouse.

Q: Growing up and working in a family business has exposed you to many aspects of the industry. What have you learned through that process?

A: Being well-rounded is important. It’s not just about having the best price or the best leadtime. You must have a connection with your customers, a quality product, and staff that care. The combination of all those things is what makes a company stand out.

In addition, the importance of taking care of the people who helped you grow along the way is something that can’t be overlooked. Whether it’s longtime customers or the employees who helped you build your company to where it is today, it’s important to reward loyalty and continue growing relationships.

Q: With labor in high demand and workers hard to find, many companies are turning to temps or high-turnover employees to fill their ranks. Often safety training is overlooked. What can companies do to ensure a safer workplace?

A: It’s important for management to lead by example. There’s a stark contrast between a company that emphasizes safety and one that doesn’t. When you walk into a new workplace and see things like warning lights, safety signs, and protective barriers, you immediately understand that safety is a high priority. It’s important for those new-hires to be in an environment that promotes safety.

Another key factor is management setting a standard for what is and is not acceptable in terms of safety. If you see an infraction, address it and correct it immediately. Over time, it becomes the culture of your business, and veteran employees begin to lead by example.

Q: Are there any statistics available on how safety can be improved by the installation of safety equipment?

A: On average, 95 people are seriously injured in a forklift accident every day. According to OSHA, the vast majority of those accidents are caused by negligence. The addition of guard rail and other steel barriers goes a long way toward protecting people, products, and other assets when those unfortunate accidents do happen.

Q: Your company makes products that not only protect workers but also protect equipment and other assets from damage. How can someone convince management that it will see a good return on an investment in safety products?

A: In a way, our products are very similar to insurance policies. You don’t always want to pay the upfront cost, but the day you have an incident, you sure are happy that you’re covered. As someone running a business, protecting your employees and assets should be a high priority.

Q: Can you share an example of safety products in action where life and property were spared because of the equipment?

A: I won’t reveal the name, but we supplied a major retail company with guard rail to create an enclosure around two exposed workstations inside one of its distribution centers. Less than a week later, we found out that a forklift had inadvertently slammed into the guard rail. The impact was so strong that it bent the rails and damaged one of the desks. Fortunately, the employee sitting at the desk was completely unharmed. Without the guardrail system in place, the employee would have likely suffered severe injuries, if not worse.

While we don’t hear these types of stories often, I have to assume that things like this happen every week. We take pride in knowing that our products are out there protecting people, even if we don’t always get to hear the success stories.