Warehouse automation systems provider AutoStore today opened its second factory to build robots for its automated storage and retrieval system (AS/RS) products, saying the location in Thailand will double its manufacturing capacity within the first year and move production closer to key markets including the U.S.

The Norwegian company has provided over 1,450 automated fulfillment systems across 54 countries, including 232 systems with 17,000 robots operating in the U.S. alone for brands like Puma, Gucci, and Best Buy.

"Since 2012, our robots have been manufactured and shipped exclusively from Poland. With increased demand in our automated fulfillment system across North America and worldwide, it’s become imperative that we opened a second robot factory to better serve current and future customers," Mats Hovland Vikse, CEO at AutoStore, said in a release. "The workforce availability, proximity to harbors and airports, favorable labor costs, and government incentives for automation companies made Thailand an ideal location for our second robot factory to power AutoStore’s North American operations."

The new factory in Thailand is expected to create around 80 direct employment opportunities in its first year, with plans to increase to 200-300 jobs by 2026. Within the next 18 months, AutoStore aims to produce 15,000 robots—doubling its current capacity to meet demand for customers in North America.

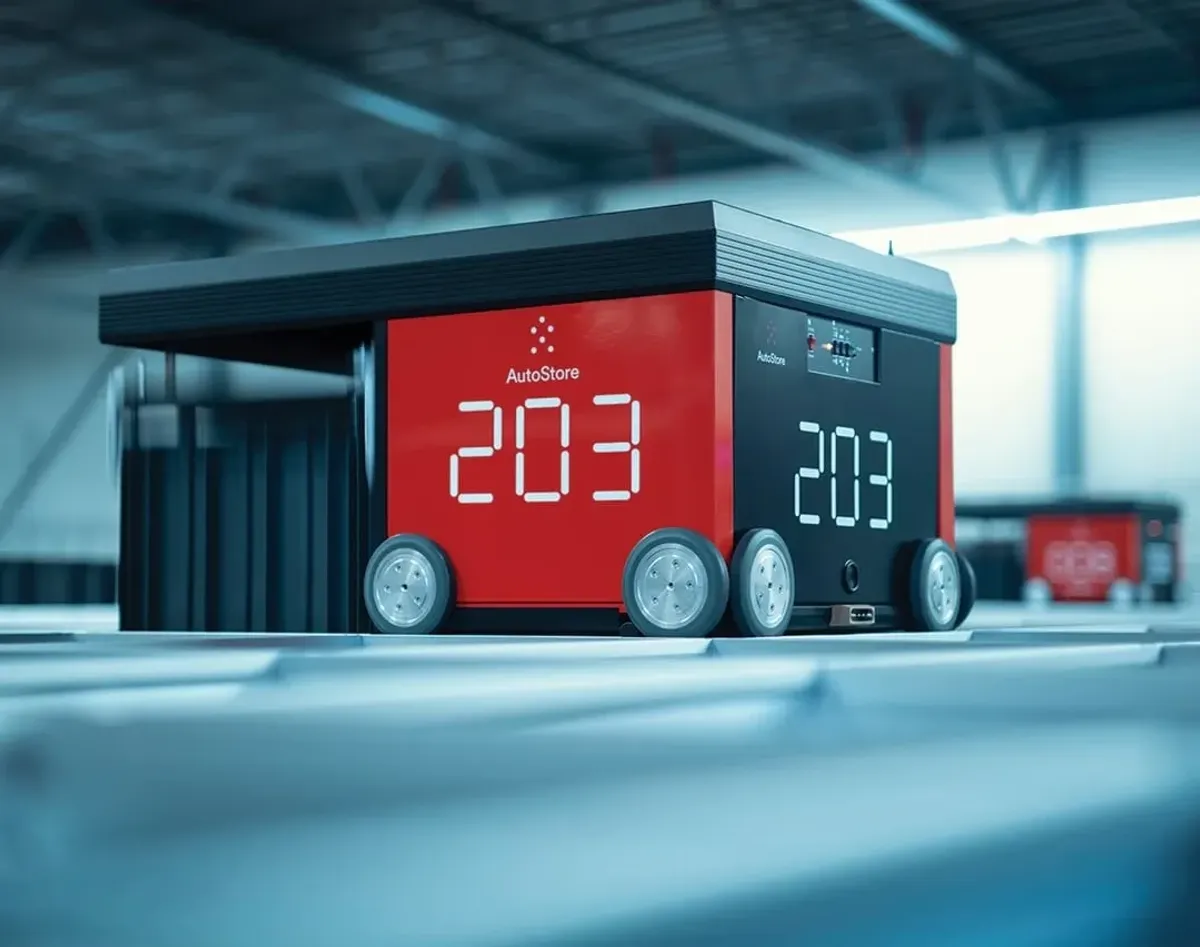

Instead of relying on shelf-based storage and manual retrieval, AutoStore employs a cube-based modular storage system using rolling robots to provide retailers with a solution that accelerates order fulfillment, maximizes warehouse space, and improves operational efficiency.