Barcode standards organization GS1 US today said it has unveiled two new guidelines to help industry users transition to more-advanced two-dimensional (2D) barcodes on product packaging in the U.S. healthcare, apparel, and general merchandise sectors.

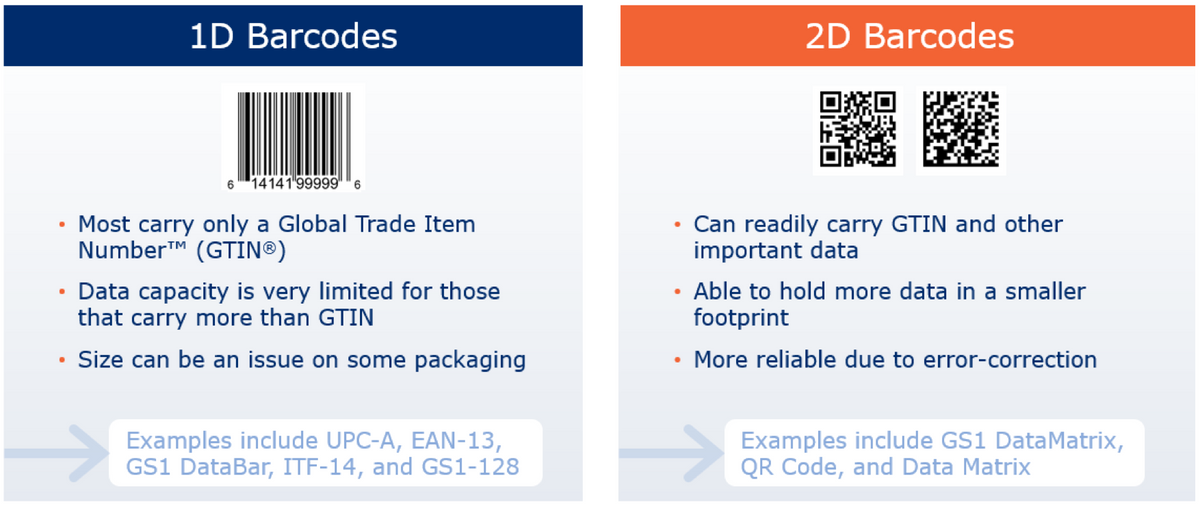

According to the New Jersey-based group, 2D barcodes such as QR codes and GS1 DataMatrix will enhance supply chain visibility, efficiency, and patient and consumer safety. Produced by a working group of retailers, brands, and solution providers in the apparel and general merchandise industries, the guideline provides practical advice for implementing 2D barcodes by 2027, a timeline set by the retail industry in collaboration with GS1 US to scan 2D barcodes at point-of-sale (POS).

More specifically, the first guideline—titled “Unlocking the Benefits of 2D Barcodes in Apparel and General Merchandise: Getting Brands and Retailers Ready for Sunrise 2027”—explains how 2D barcodes can be used to provide improved product information, traceability, authentication, and streamlined checkout and returns.

And the second guideline—titled “Unlocking Benefits of GS1 DataMatrix in Non-Retail Healthcare”—is designed to assist non-retail healthcare stakeholders in implementing GS1 DataMatrix 2D barcodes in channels such as hospitals, pharmacies, clinics, infusion centers, long-term care facilities, and ambulances.

“As technology and consumer expectations for more information about products evolve, the demand for enhanced product information goes beyond the traditional role of UPC barcodes,” Melanie Nuce-Hilton, senior vice president, community engagement, GS1 US, said in a release. “While some apparel and general merchandise brands already utilize 2D barcodes with GS1 Digital Link for consumer engagement, there is a pressing need to extend this capability to POS to allow for a single standardized way to meet supply chain needs and consumer requirements.”

“As healthcare products are sold in both retail and non-retail environments, a coordinated approach to 2D barcodes ensures labeling consistency and efficiency for brand owners. GS1 DataMatrix is already being adopted across healthcare to comply with regulation; to avoid confusion and align on a single barcode, GS1 DataMatrix is recommended by industry as a preferred data carrier for healthcare products across both areas," Nuce-Hilton said.