A California robotics startup backed by Amazon plans to launch the first production model in January of its automated storage and retrieval system (AS/RS) with an unnamed “tech-forward 3PL in North America.”

San Carlos, California-based Instock Inc. today announced that it had raised $3.2 million in new funding, led by Amazon Industrial Innovation Fund, bringing its total seed financing to $6.2 million. The round was co-led by OneWay Ventures and Lux Capital, and funding participation also includes Commerce VC, u.ventures, Cybernetix Ventures, “and other investors active in the robotics and eCommerce ecosystem.”

Instock says its technology will “democratize” AS/RS applications by using gravity-defying robots sold through a robotics-as-a-service (RaaS) model. “Our mission is to empower business operators with radically accessible goods-to-person automation,” Rebecca Dyer, Instock’s chief of operations, said in a release. “We provide a tool for high-density storage and quick retrieval of goods that is affordable, easy to use and delivers value on Day 1.”

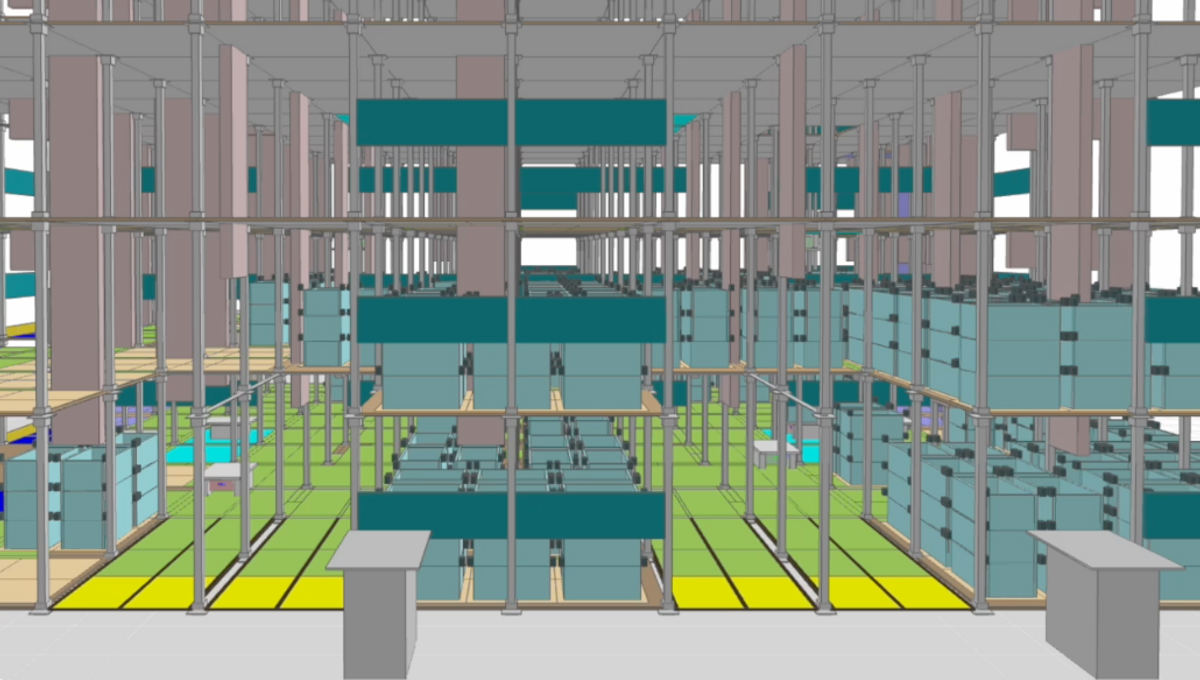

According to Instock, its modular racking can be built in various shapes up to the clear height of a building. Autonomous mobile robots (AMR’s) drive inside the racking along floors, walls, and ceilings to collect bins and present them to operators picking and packing orders at ground-level workstations. Since the mobile robot is the only moving part of the solution, system maintenance is easily encapsulated for either the end user or for a technician located off-site, the firm says.

Instock plans to provide its AS/RSs to fulfillment operators who are constantly challenged to improve speed, efficiency, accuracy and service, while simultaneously driving down costs and maintaining a competitive advantage.

"There is a growing need for highly automated, space-efficient buildings in logistics,” Franziska Bossart, the Head of the Amazon Industrial Innovation Fund, said in a release. “Instock’s ASRS capabilities have the potential to improve the number of shipments per day and storage density in space constrained environments – all of which can enable faster delivery to customers and lower costs. Part of what makes Instock’s ASRS unique is that it can be easily retrofitted into existing environments, allowing for plug-and-play automation in a wide variety of building types. We’re excited to support Instock’s vision as they scale and offer production systems more broadly.”