Fortna: Vistar's sweet setup

Duration: 0:03:26

Release Date: Dec 13, 2021

Like many companies adopting new distribution practices to address changing business environments, Vistar realized a critical need and turned to Fortna as its design and integration partner for a new distribution facility.

The company is one of the nation's largest distributors of candy, snacks, and beverages found in office lunch rooms, vending machines, theater concession stands, retail checkout counters, and the snack areas of the hospitality industry.

It used to be that Vistar would ship mixed pallets of products to customers, but like most wholesale suppliers, it found its customers wanted smaller quantities shipped to them more often. That meant its distribution facilities had to find ways to do more piece picking for orders to ship via parcel carriers. Vistar also needed better processes to fill direct-to-consumer orders, including drop shipments to end-users on behalf of its customers.

The manual facilities in the company's network were not up to these new requirements, and so it was decided that the "pick and pack" operations from four facilities serving the East Coast needed to be consolidated into one highly automated operation in Lebanon, Pa.

"We wanted to create a center of excellence for pick and pack," explains Mike Fernstrom, Vice President of Retail Automation at Vistar. "This consolidated facility allows us to reach the entire East Coast within two days. We are ideally located geographically, and it gives us room to grow."

"We looked to them to design the right operation, but also with the right equipment," recalls Fernstrom. "We chose Fortna because they are agnostic to equipment manufacturers, so they can help us apply the right tech to the right solution. They make it work."

AUTOMATED CANDYLAND

The equipment chosen for the 277,000-square-foot facility assures that orders are processed quickly and accurately, while also providing capacity to grow. Denser storage now allows Vistar to increase its offerings to more than 10,000 different products. A three-level pick module holds most goods in pallet flow racks, carton flow racks, and shelving. Radio-frequency (RF) devices direct workers to pick items into totes staged on carts.

Most of the faster-moving items are selected from ground-level storage racks. Here, small innovative tuggers maneuver easily through the racks, each pulling two carts holding 14 totes. For flexibility and greater efficiency, the design has workers doing a combination of cluster picking and discrete order selection into the totes.

Vistar and Fortna chose a Perfect Pick goods-to-person system supplied by OPEX Corporation to hold a large number of products. The system uses small robots called iBOTs that move within an aisle between two rows of racks holding some 5,000 totes. The iBOTs move totes holding needed items to two picking stations, located on opposite ends of the aisle. Pick-to-light technology is employed at the stations to provide fast and accurate picking into multiple order totes.

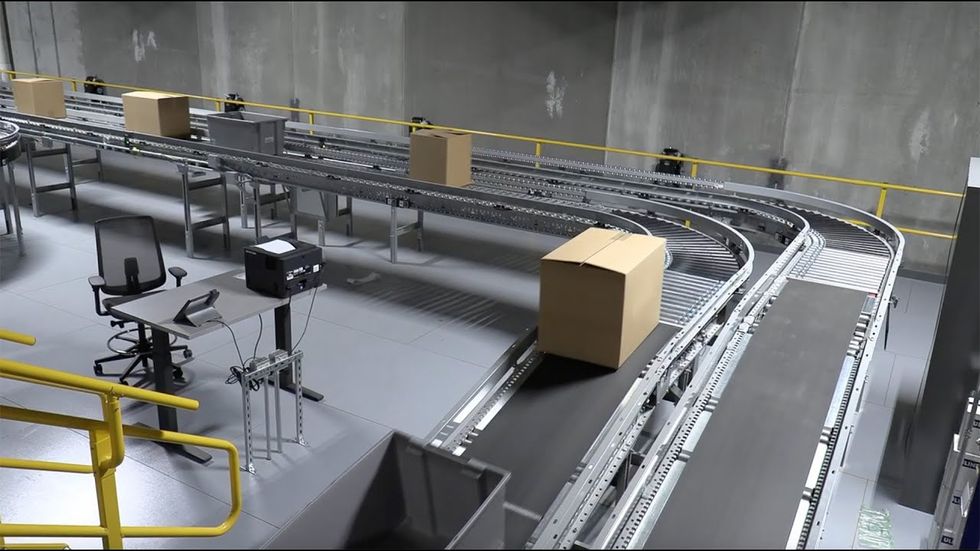

The facility also utilizes four sorters. One routes totes to various pick areas; a packing sorter delivers picked orders to 48 pack stations; a post-packing sorter sends completed cartons to be void-filled, sealed, and labeled; and a shipping sorter delivers packed cartons to outbound docks.

Additionally, Vistar is able to offer value-added services for customers, such as creating cartons of mixed products and cases holding smaller quantities. One area of the building also contains packaging equipment where fresh candy is bagged.

Since opening its doors last October, the facility is more efficient, offers increased throughput capabilities, and has reduced the reliance on difficult-to-find labor.

"With the larger building, we have additional capacity and room to grow," adds Fernstrom. "This building is the platform that will allow us to grow additional business, either B-to-B or B-to-C services. So, we are really excited about the opportunities that this building has given us."

Sponsored By Fortna

Sponsored By Fortna